|

Since 1959, SCHMELZMETALL group is a leading manufacturer of copper based high-performance alloys.

We are represented all over world by internationally acting sales teams and branches. Our HOVADUR® alloys stand for highest quality and a fair price-performance ratio.

Due to nearly 60 years of experience in producing high vacuum copper alloys we achieve a high uniformity in quality. We master the further processing to semi-finished products and finished parts. We know how to apply our alloys optimally in your processes and applications.

Our experience – Your advantage:

You will receive customized high-performance alloys with properties exactly matched to your requirements!

►Download Image brochure >>>

Thrust chamber of Ariane 5 rocket. Schmelzmetall is since 1996 significantly participating on the developing of the alloy for the thrust chamber

Alloys and Dimensions

HOVADUR® Alloys

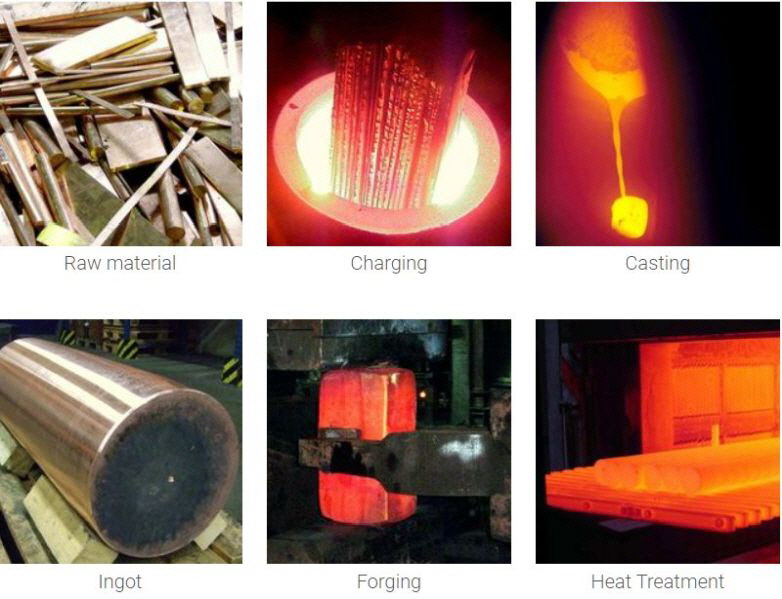

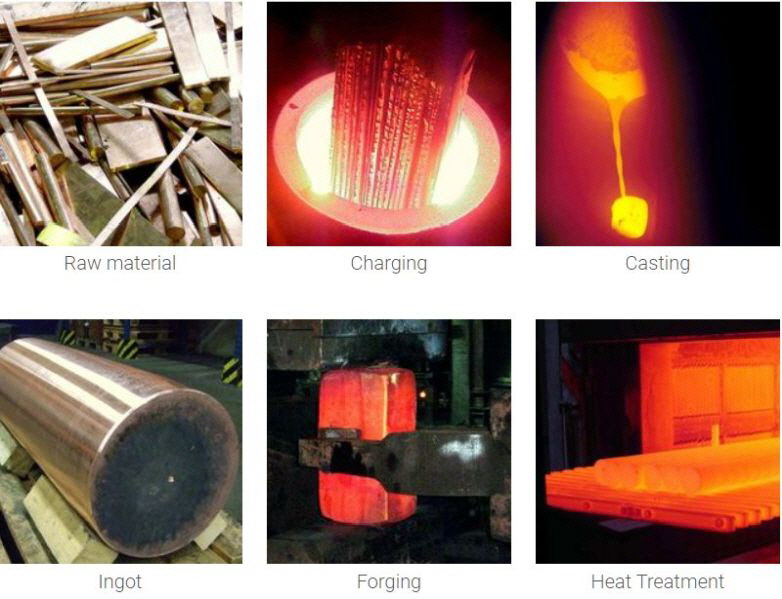

The basic materials for all alloys are pure metals such as copper, nickel, cobalt, chromium, beryllium and zircon. These metals are prepared in correct quantities and filled into the crucible of the vacuum furnace.

Recharging during the melting process is carried out via a lock chamber. Once the melting process being finished, the alloy is cast under vacuum into one or several moulds.

Due to this procedure under complete absence of air, a very high purity and quality of the alloy are achieved. Negative environmental influences are completely excluded.

►Further information can be found here.

Special Alloys

HOVADUR® alloys stand for highest quality.

Since 1959, SCHMELZMETALL group is a leading manufacturer of copper based high performace alloys

You will receive customised high performance alloys showing the properties precisely in line with your requirements.

We are your competent partner for developing and supplying the optimum alloy. We even realize quantities less than 1000 kg!

►Further information can be found here.

Formats

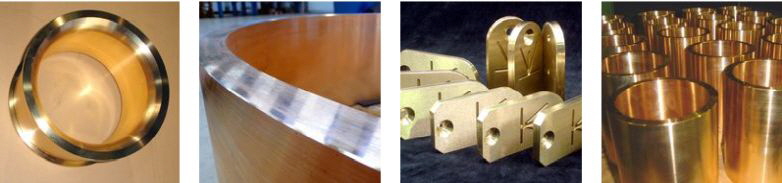

Semi-finished HOVADUR® Alloys

We supply HOVADUR® alloys in the following formats:

• Bars >>>

• Discs and rings >>>

• Forged round bars and plates >>>

• Ingots >>>

• Finished parts >>>

SCHMELZMETALL supplies forgings up to a weight of 1500 kg. Pieces cut from plate, special dimensions and profiles can be produced according to your requirements. Due to our extensive stock, we are normally able to supply you within a very short time.

Your product has to have special properties? No problem! Our specialists like meeting new challenges.

►Further information can be found here.

Applications

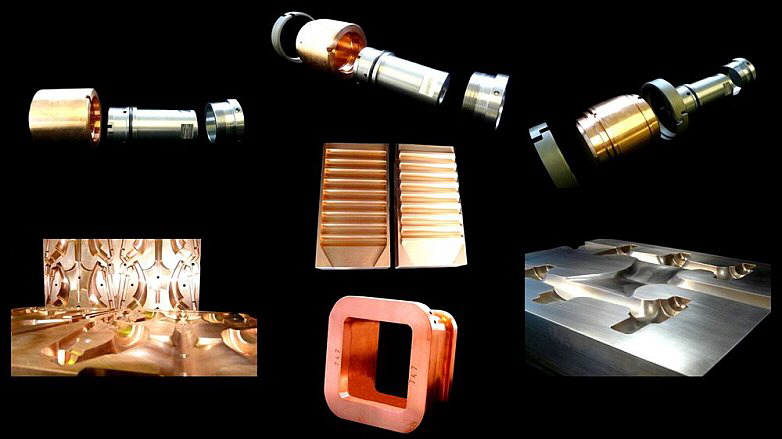

HOVADUR®: Special alloys for special applications

SCHMELZMETALL alloys are in demand all over the world whenever special values concerning thermal conductivity, electrical conductivity, strength and gliding properties are requested.

We stand for competent technical advice, we supply pre-machined parts or take over the revised construction of your existing parts, of course on demand also according to your sample. Smooth order processing is ensured due to the quality and the wide range of our machinery as well as many years of experience of our skilled and committed production team.

Your obvious advantage:

• One supplier

• One price

• 100% SCHMELZMETALL quality

Resistance Welding

HOVADUR® alloys combine excellent electrical conductivity and maximum hardness specific for the material.

Our alloys are characterized by:

• Optimal welding properties

• High resistance to wear

Your advantages:

• Increase of process reliability

• Increase of tool life

• Reduction of machine down-time

Our range of products:

• Electrodes

• Electrode holders

• Special electrodes

• Welding cables

• Laminated strips

• Welding wheels

• Welding tongs

►Further information can be found here.

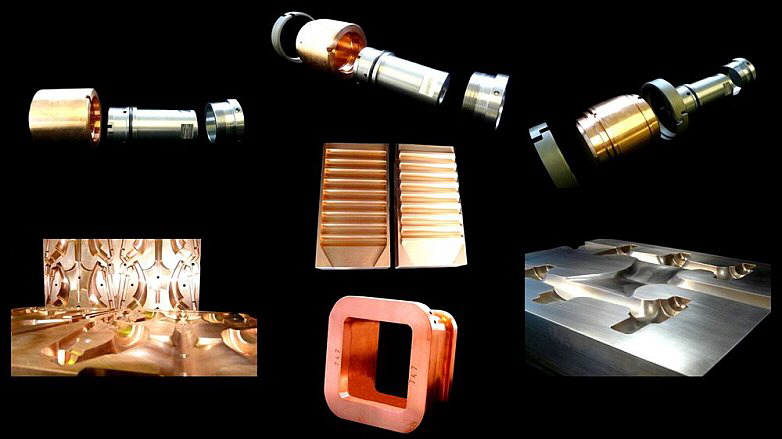

Plastic Injection Moulds

Requirements on today’s injection moulds are partly contradictory. The best quality of the moulded part has to be achieved in the shortest cycle time. A combination of serveral properties contribute to making HOVADUR® alloys well suited for satifying these requirements.

Our alloys are characterized by:

• High thermal conductivity

• High elongation

• Good machining

• Good surface coatability

• Good structuring properties of surfaces

• Good chemical stability

Your advantages:

• Shortest cycle time

• Highest quality of the moulded part

• High added value

• Low machining costs

• Conformal cooling

Our range of products:

• Semi-finished products for your mould construction

• Mould inserts pre-machined close to the contour

• Steel / copper composite according to your guidelines

• Injection nozzles and ante-chamber bushings

• Generatively produced mould inserts

►Further information can be found here.

Casting Technology

HOVADUR® special alloys showing excellent thermal conductivity are essential materials for construction in casting technology.

Your advantages:

• Low piston wear

• Increase of life time of the shot chamber

• Simple handling of the piston system

Our rage of products:

• Pistons > Piston Adapter Systems

• Shot chambers

• Die venting systems

• Moulds for continuous casting

►Further information can be found here.

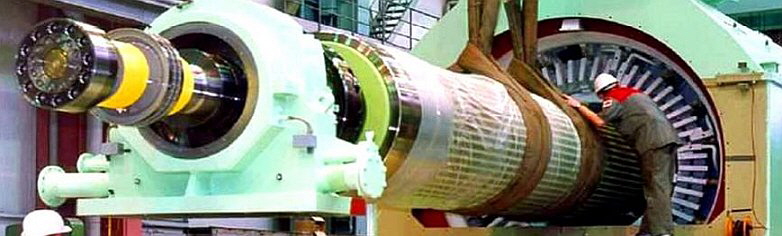

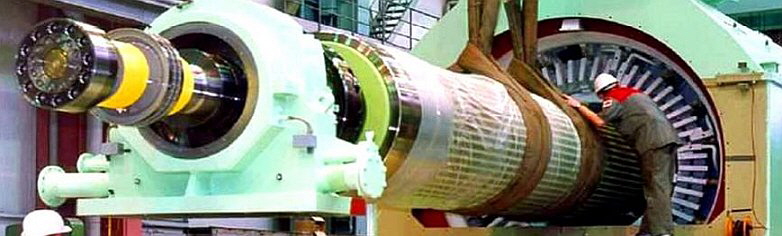

Electrical Engineering

Due to their excellent physical properties, our HOVADUR® special alloys are indispensable when it comes to safety and reliability.

HOVADUR® alloys are characterized by:

• High electrical conductivity

• Excellent long life cycle

Your advantages:

• Optimal combination of high strength and good conductivity

• Suitable for vacuum applications

• Magnetically neutral behaviour

Our range of products:

• Contact springs

• High voltage circuit breaker

• Cores for solenoid coils

• Pole connector

• Coil for HMFL (High Magnetic Field Laboratory)

• Circuit rotor rings

Our HOVADUR® special alloys contribute to reducing your maintenance and repair costs to a minimum.

►Further information can be found here.

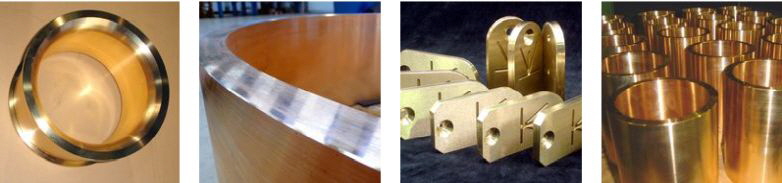

Mechanical Engineering

HOVADUR® and HOVADUR® B alloys: Our special alloys for construction in mechanical engineering

HOVADUR® and HOVADUR® B alloys are characterized by:

• Excellent thermal conductivity

• Special sliding properties

• Extraordinary resistance against many chemical substances

• No sparks (explosion prevention!)

Your advantages:

• High hardnes and compressive strength

• Easy to maintain

• High resistance to wear

• Good machining properties

• High resistance against corrosion

Our range of products:

• Wedge bars

• Clamping bars

• Bearing bushes

• Sliding and guiding elements

HOVADUR® alloys are especially suitet for highly strained bearings, chemical-resistant fittings, non-sparking parts as well as thermally conductive components for special machine construction.

►Further information can be found here.

Plain Bearings

Due to their extraordinary combination of strength, resistance against corrosion and sliding properties, our HOVADUR® B alloys are especially suited for use in highly strained bearings.

Bushes and linear motion guides made of HOVADUR® B are used in cases where standard alloys, such as red brass are overstrained.

In case of even higher requirements and extreme strain, we also trust in our partner Materion and their copper-nickel-in alloys Toughmet®.

►Further information can be found here.

Quality

SCHMELZMETALL masters processes and creates customer benefit due to quality

SCHMELZMETALL disposes of a group-wide management system. We are certified for the development, manufacturing and distribution of semi-finished and finished products made of copper and nickel alloys. Our certification partner is Bureau Veritas Certification.

►You can find our certificates here..

Download

Flyer Powder (PDF file)

Professional article

Copper alloys and multi-alloy aluminium bronzes

An optimum temperature control does the trick

Shortest cycle time and optimum part quality are the main requirements which have to be met by highquality injection moulds. The main focus lies on the optimum temperature control of the mould. The following article deals with the role of special copper alloys and multi-alloy aluminium bronzes produced by the Schmelzmetall AG.

Read Article (PDF-file, 516 KB)

|